WHY THIS MATTERS IN BRIEF

Many 3D printers still only print one material, or at best switch between different materials very slowly, this new printer therefore opens up a host of new use cases.

Interested in the Exponential Future? Connect, download a free E-Book, watch a keynote, or browse my blog.

Interested in the Exponential Future? Connect, download a free E-Book, watch a keynote, or browse my blog.

3D printers are revolutionising manufacturing by allowing users to create any physical shape they can imagine on demand – everything from Adidas sneakers and satellites 3D printed in orbit through to parts for jet engines and even interplanetary rovers. But as advanced as all this sounds the fact remains that most commercial 3D printers can only print products made out of a single material and inkjet printers that are capable of multi-material printing are limited by the physics of droplet formation – something that researchers recently tried to solve by creating a 3D printed that printed using sound.

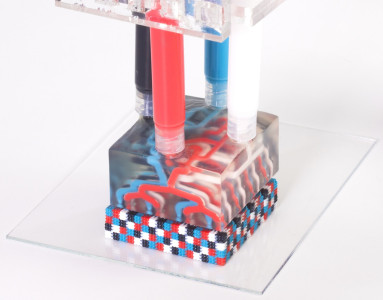

Now though researchers at Harvard University have 3D printed a bunch of soft robots using a new 3D printing technique that they’ve catchily called Multi-Material Multi-Nozzle 3D (MM3D) printing which uses high speed pressure valves that let the printers nozzles rapidly switch between up to eight different printing materials up to 50 times a minute that lets them print complex shapes in a fraction of the time using conventional printheads. The research is reported in Nature. The breakthrough could also help speed up the development of 3D printed electronic devices aswell as the manufacturing of flexible and soft electronics, for example, for use in wearables and other applications – something that would really catch the eye of manufacturers and product designers all around the world.

“When printing an object using a conventional extrusion-based 3D printer, the time required to print it scales cubically with the length of the object, because the printing nozzle has to move in three dimensions rather than just one,” said study author Mark Skylar-Scott, Ph.D. “MM3D’s combination of multi-nozzle arrays with the ability to switch between multiple inks and different materials rapidly effectively eliminates the time lost to switching printheads and helps get the scaling law down from cubic to linear, so you can print multi-material, periodic 3D objects much more quickly.”

The key to MM3D printing’s speedy ink-switching is a series of Y-shaped junctions inside the printhead where multiple ink channels come together at a single output nozzle. The shape of the nozzle, printing pressure, and ink viscosity are all precisely calculated and tuned so that when pressure is applied to one of the “arms” of the junction, the ink that flows down through that arm does not cause the static ink in the other arm to flow backwards, which prevents the inks from mixing and preserves the quality of the printed object.

By operating the printheads using a bank of fast pneumatic valves, this one way flow behaviour allows the rapid assembly of multi-material filaments that flow continuously out from each nozzle, and enables the construction of a 3D multi-material part. The length of the ink channels can also be adjusted to account for materials that have different viscosities and yield stresses, and thus flow more quickly or slowly than other inks.

“Because MM3D printing can produce objects so quickly, one can use reactive materials whose properties change over time, such as epoxies, silicones, polyurethanes, or bio-inks,” said co-first author Jochen Mueller. “One can also readily integrate materials with disparate properties to create origami-like architectures or soft robots that contain both stiff and flexible elements.”

To demonstrate their technique, the researchers printed a Miura origami structure composed of stiff “panel” sections connected by highly flexible “hinge” sections.

Previous methods of building such a structure require manually assembling them together into stacked layers – the MM3D printhead was able to print the entire object in a single step by using eight nozzles to continuously extrude two alternating epoxy inks whose stiffnesses differed by four orders of magnitude after being cured. The hinges withstood over 1,000 folding cycles before failing, indicating the high quality of the transitions between the stiff and flexible materials achieved during printing.

MM3D printing can also be used to create more complex objects, including actuating robots. The research team designed and printed a soft robot composed of rigid and soft elastomers in a millipede-like pattern that included embedded pneumatic channels that enable the soft “muscles” to be compressed sequentially by a vacuum, making the robot “walk.” The robot was able to move at nearly half an inch per second while carrying a load eight times its own weight, and could be connected to other robots to carry heavier loads.

“This method enables the rapid design and fabrication of voxelated matter, which is an emerging paradigm in our field,” said Mueller. “Using our broad palette of functional, structural, and biological inks, different materials can now be seamlessly integrated into 3D printed objects on demand.”

[…] I talked about the development of a lightening fast revolutionary multi-material 3D printer from Harvard University that, among other things can 3D print funky looking soft robots and breaks […]