WHY THIS MATTERS IN BRIEF

Dirty industrial processes use huge amounts of energy and heat to create cement, glass, and steel, and now we have a way to replace them with green energy.

Interested in the Exponential Future? Connect, download a free E-Book, watch a keynote, or browse my blog.

Interested in the Exponential Future? Connect, download a free E-Book, watch a keynote, or browse my blog.

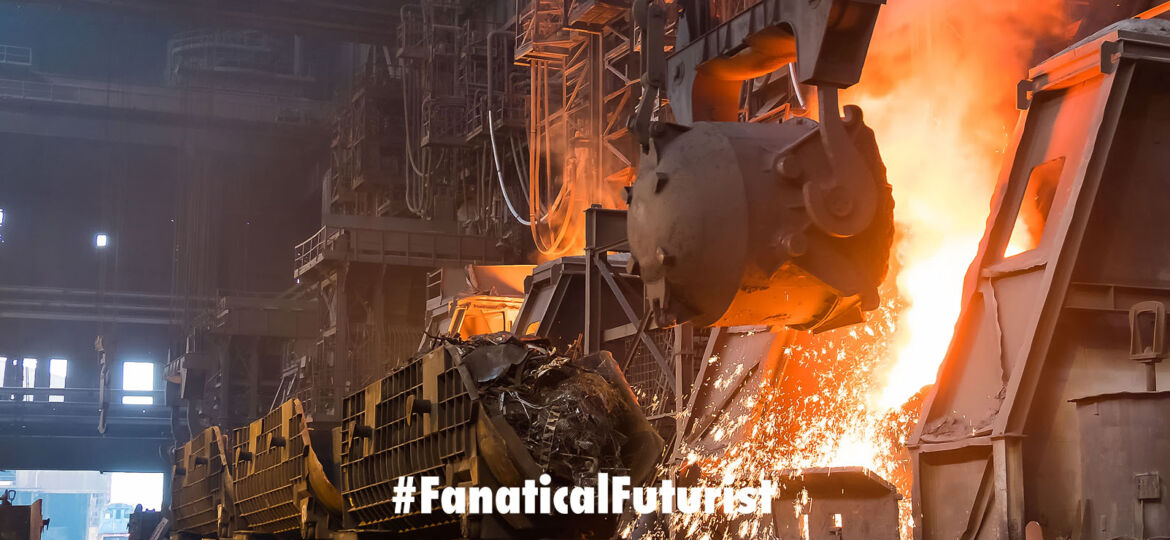

Creating cement, glass, and steel normally uses a huge amount of electricity because, for example, in order to create molten steel companies need to power huge blast furnaces that run a thousands of degrees Celcius. Now though a startup backed by Bill Gates says it has managed “to harness solar energy to greater effect than ever before,” and generate enough heat from a field of mirrored panels to drive the production of all three and replace the need to use fossil fuels in these industrial processes. Furthermore, and in keeping with our modern age, this extra heat and efficiency was made possible by using Artificial Intelligence (AI) that managed to perfectly position the mirrors to concentrate sunlight in the most intense way in order to reach the extreme temperatures needed.

The company, called Heliogen, claims that its focussed beams of light are able to create a so called “Solar Oven” that reaches 1,000 degrees Celsius (1,832 degrees Fahrenheit) – something that hasn’t been done before in a commercial setting. And that means solar power could replace fossil fuels for a host of industrial jobs and processes, and not just be stuck providing electricity to homes and offices.

“The world has a limited window to dramatically reduce greenhouse gas emissions,” says Bill Gross, CEO and founder of Heliogen. “We’ve made great strides in deploying clean energy in our electricity system. But electricity accounts for less than a quarter of global energy demand.”

“Heliogen represents a technological leap forward in addressing the other 75 percent of energy demand – the use of fossil fuels for industrial processes and transportation. With low cost, ultra-high temperature process heat, we have an opportunity to make meaningful contributions to solving the climate crisis.”

Energy production through these concentrated solar power plants isn’t a new idea, but Heliogen has been able to get its systems to reach temperatures close to double what’s currently possible, which opens up a host of new opportunities, and in terms of the AI used, I’m mainly talking about machine vision here that includes the use of high-resolution cameras to work out the position of each individual mirror, backed by complex algorithms that can optimise the angle they’re set at.

Further down the line, Heliogen is confident that it can use its systems to generate temperatures of up to 1,500 degrees Celsius (2,732 degrees Fahrenheit). That’s enough to create 100 percent fossil-free fuels like Hydrogen or Syngas, through CO2 splitting and water-splitting processes.

Hydrogen fuel has long been talked about as a clean, eco-friendly way of meeting our transportation needs, while syngas, or synthesis gas, can be used for heating or converted into biofuel. The problem with both is being able to produce them practically and affordably at scale.

With heat-generating fossil fuel processes responsible for around 10 percent of global CO2 emissions, the system that Heliogen has put together promises to make a big dent in the amount of carbon dioxide we’re putting into the atmosphere. But all of this needs scaling up though, which means plenty more investment is going to be required – as well as solutions for storing the generated energy on days when the Sun isn’t shining. With that in mind though we’re not going to be able to ditch fossil fuels in the short term, but Heliogen’s AI tech might just have got us a big step closer to ditching them in the medium term.

“[Heliogen’s] capacity to achieve the high temperatures required for these processes is a promising development in the quest to one day replace fossil fuel,” says Bill Gates, the ex-Microsoft boss who is one of the early backers of the solar startup. “And, if we’re going to get to zero carbon emissions overall, we have a lot of inventing to do.”

As an engineer with over 25 years working in the steel foundry sector I think money should be invested in making fossil fuel energy production cleaner . Steel foundries make thousands of castings that are essential for industry and modern life . Where are we going to have these steel foundries ,in the middle of the dessert so that they can be near one of these giant mirror energy production facilities , how you channel the heat to the inside of the furnace ? have you calculated how this type of generation will impact steel prices ? I would like to have more information . Thanks .