WHY THIS MATTERS IN BRIEF

Being able to 3D print materials with different and unique properties opens up a whole new range of use cases and applications, from car design to implanted medical devices, to soft robots and beyond.

A two year collaboration between BMW and MIT has produced the world’s first 3D printed inflatable material that can change its shape and stiffness on command. Consequently, it could be used in designing highly customizable and multifunctional interiors, for example, for self-driving concept cars like Audi’s Long Distance Lounge (LDL) or Toyota’s e-Palette concepts, as well as implanted medical devices and a million things besides.

Anyway, back to cars, since, after all this is BMW’s gig… If the car of the future really is autonomous, and it’s looking highly likely, then we may be about to witness a radical shift in the form and function of their interiors. Without the need for dashboards, front facing seats, pedals or steering wheels, we’re going to be left with nothing more than an empty space that needs filling with stuff. Whatever stuff we like. So as a result we could be heading toward seats and compartments that morph into different shapes to meet different needs at the touch of a button. And even these cars wheels could be different in the future as Goodyear recently pointed out with their revolutionary new spherical designs…

See the material in action

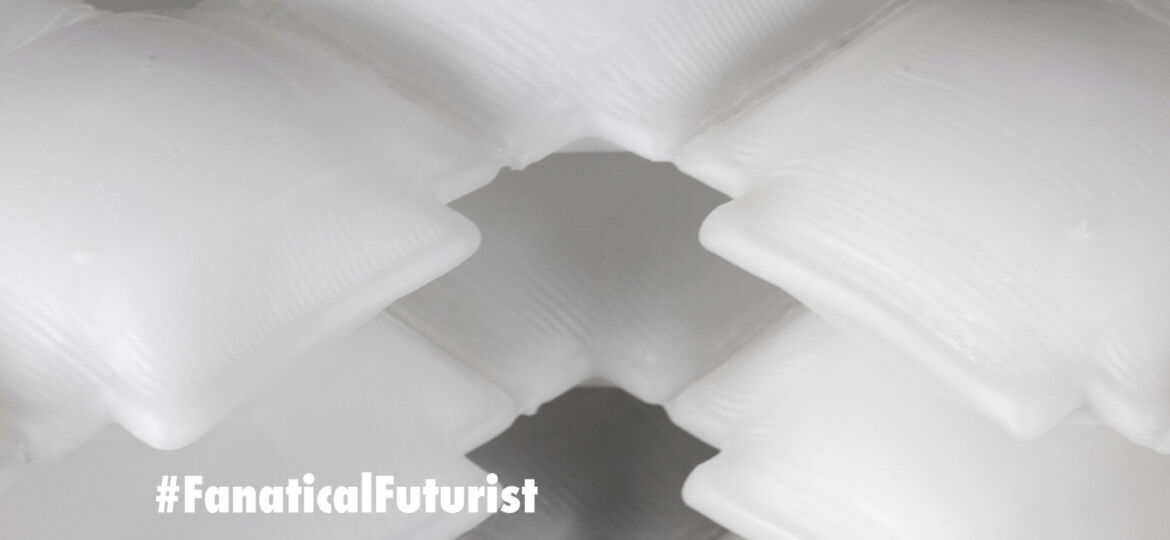

We’re talking, almost, about the complete reinvention of the car, which is why I firmly believe we’re actually witnessing the death of the car as we know it. And the new 3D printed inflatable material might just be the ticket for all these new fancy interiors. The material, which was created using a combination of techniques, including Rapid Liquid Printing and soft robotics, is made up of objects akin to printable balloons that can change their shape and stiffness in a matter of seconds.

Building inflatable materials of this kind would have previously required complex electromechanical devices or advanced moulding techniques, but these “liquid-printed pneumatics” can be manufactured by simple 3D printing in nothing more than silicone.

According to the researchers, the sample inflatable objects can be customized to any size or shape by manipulating air pressure in any one of their seven independent chambers.

“There is no need to lock the car of the future into any particular shape. Interiors could even take on malleable, modular uses,” says Martina Starke, head of BMW Brand Vision, “this adaptive material technology points towards a future of transformable surfaces for adaptive human comfort, cushioning and impact performance.”

The material is on display at the exhibition The Future Starts Here in London.

Source: BMW