WHY THIS MATTERS IN BRIEF

Transporting equipment into space is very, very expensive so NASA has turned to 4D printing to help it create new materials and types of space craft.

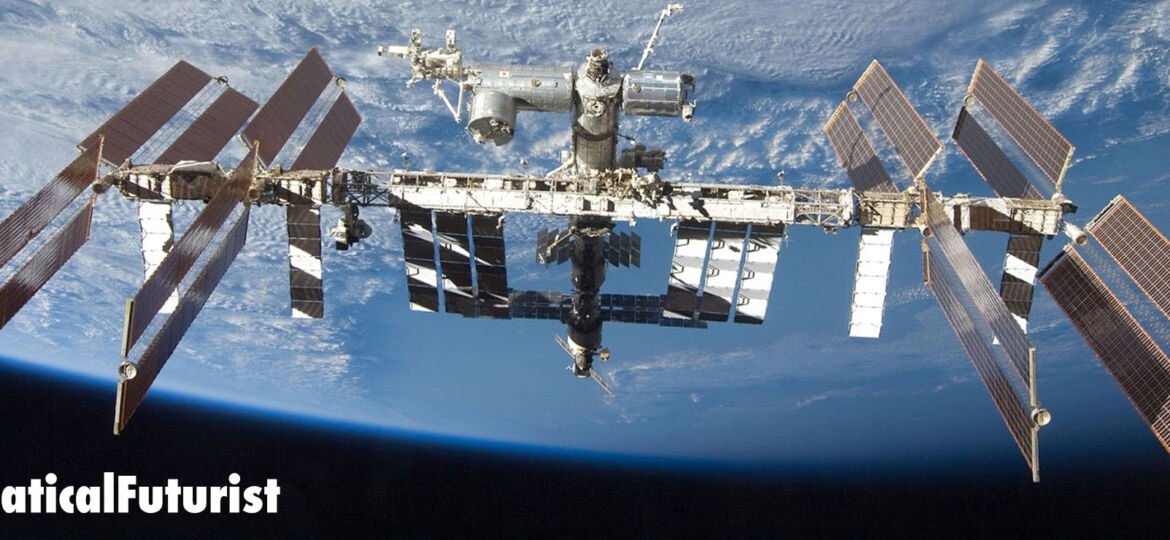

Space is a harsh unforgiving environment and just getting into orbit is still, despite Elon Musk and SpaceX’s disruptive re-useable rockets, and new futuristic plasma engines, an expensive endeavour and as a result organisations, like NASA, often need to think long and hard about how they conquer the last frontier – whether it’s by creating genetically modified astronauts that photosynthesise, yes, you read that right, or futuristic materials.

Today the average cost of transporting a pound of equipment into space is $10,000 and in the past to minimise the weight of their payloads NASA has been experimenting with inflatable habitats for the International Space Station (ISS) and shape shifting rods. Now though they’ve turned their attention to creating multi-purpose 4D printed materials.

Over the past two years the teams at NASA’s Jet Propulsion Laboratory (JPL) have been working on creating a metallic space fabric made of interlocking stainless steel squares that looks a lot like chain mail.

Unlike it’s ancient counterpart though the new fabric isn’t welded together, instead a 3D printer extrudes stainless steel as a continuous sheet of material with different properties on each side. On the front of the fabric, are rows of shiny, flat squares that reflect heat and light, while on the back, a series of interlocking loops help the fabric absorb heat, and together, the single piece of material acts like a super strong shield that can protect astronauts and space craft from the deadly ravages of space.

The fabric isn’t special in its functionality, per se, NASA already uses materials on its spacecraft that reflect heat, absorb heat, and protect them from flying debris but until now, NASA didn’t have a single material that could do all three.

“We wanted to see if a structure could do something beyond being a static piece of material,” says Raul Polit Casillas, a systems engineer at JPL who worked on the new fabric.

I know what you’re all thinking now – I talked about a 4D printed material but so far I’ve only talked about 3D printing, so let’s add that extra dimension right now.

NASA was only able to bake multiple properties into the single material thanks to the wonders of 4D printing – an ascending manufacturing technique that uses a 3D printer to layer multiple textures and geometries into a single design.

MIT researcher Skylar Tibbits, who’s appeared on my blog before, the last time when we discussed 4D printed space stations that could assemble themselves in space, coined the phrase several years ago to show how a 4D printed material could shape shift or self assemble. Using 4D printing, for instance, engineers could program a piece of metal to unfold at a certain heat or design a plastic to expand or contract under certain environmental conditions. Or, in the case of NASA’s space fabric, a fabric with flexible geometry that can both reflect and radiate heat.

Unlike traditional sheets of metal the chain mail can bend and fold with minimal effort while still remaining strong and this makes it valuable, and given how it’s manufactured it could be printed in situ on the space craft, or the ISS, and used to deflect heat on sensitive components like antennas and reflectors. It could just as easily be used on missions to Jupiter’s moon Europa, where the rough side would act like tire treads on the moon’s icy surface, or as armour for astronauts and vessels.

“Of course, you could use this for fashion, too,” says Casillas.

NASA is still at the beginning of its 4D printing journey so naturally Casillas says there’s a lot more to come adding that in time he expects his team to develop materials with more advanced built in capabilities such as the ability to move electrons, transfer energy, and shape shift.

“[The point] is to increase the science we can do per kilogram,” he adds, and from the looks of it we should expect some more very cool science soon.

[…] steel structure for NASA: A Spanish engineer named Raul Pulido Casillas has developed wire mesh-like structure for NASA with the help of 4D printing. The structure is made of attached steel pieces. It […]

[…] space and have it assemble itself in orbit? Well, up until recently the closest we got was 3D and 4D printing structures in space that self-assembled. Now though researchers at MIT Media Lab have tested modular tiles that […]