WHY THIS MATTERS IN BRIEF

Up until now most self-healing materials have either been hard, or soft, and that narrows their number of applications, this new material is the first to have the best of both worlds.

Imagine a smartphone, or window, that can heal from cuts and scratches just like the human body can. For researcher Ming Yang and his team at the Harbin Institute of Technology in China , who also, strangely enough, have been involved in the development of China’s first generation of supersonic submarines, you heard me right, it’s not really a question of imagining anymore because they’ve developed a new kind of smart coating that manages to be both soft and hard, not unlike our own skin.

“We designed a self-healing coating with a hardness that approaches tooth enamel by mimicking the structure of the human skin,” said Yang in a recent interview, “this is the most desirable property combination in the current self-healing materials and coatings.”

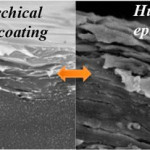

The new coating under the microscope

As described in a paper the team published in ACS Nano Yang says that he believes there is a global need for better, more ubiquitous self-healing materials.

“Nowadays people always talk about environment and energy,” he says, “a self-healing material can help save companies and individuals a lot of money and energy in a smart, environmental friendly way. But the current self-healing materials and coatings are typically soft and wear out quickly [and] this can bring potential problems about the management of plastic waste.”

The teams new material, it’s thought, could go some way to help solving those waste problems because it’s better than everything that’s come before it, combining the flexibility of a soft coating and the resilience of a hard coating without the short lifespan of the former or the brittleness of the latter. In other words, the best of both worlds.

“The trick is to use artificial materials in a natural way,” says Yang, “the multilayer structure of our new self-healing material is the key. By placing a hard layer containing graphene oxide on top of a soft layer, we create a smart hybrid material you can get the most out of.”

The graphene oxide material used in the coating’s top layer is harder than skin cells, offering a toughness closer to that of teeth enamel, but the amazing thing, according to Yang, is that the coating’s hard and soft layers can work together to create healing properties that neither could accomplish on its own.

“It’s exciting to see how we can integrate demanding properties in two natural structures, namely the self-healing property found in skin and the mechanical stiffness and hardness found in tooth enamel, into an artificial smart coating,” says Yang, “and this design principle is likely going to be useful for any future self-healing polymer system.”

The result is a potentially much longer-lasting smart coating that can protect anything, from buildings and windows to computer displays and smartphones from scratches, while another of its features, being able to kill bacteria, means it could also be useful in the healthcare industry to help create self-healing biomedical devices including endoscopes, insulin pumps and pace makers. Now it’s just a question of turning a lab creation into something that can actually reach the market, but there are some practical issues that will need to be solved first in order for that to happen.

“The current research uses molecular level assembly to achieve the desirable structure,” says Yang, “in the future, we will need a more efficient way to accelerate the production of the material. Spray-assisted coating can be a good choice. We are also trying to apply similar design principle to other self-healing polymers especially those are already commercially available.”

Still, Yang says he is optimistic that this smart coating could finally usher in the era of self-healing, scratch-proof smartphones in the relatively near future.

“I am positive that a prototype product based on our design can be available in one to two years,” says Yang, “we still have a long way to go however before we can create a mature product and we’ll need a lot of customer feedback and the participation of investors and potential partners. I will not be surprised if this would take five years or more.”