WHY THIS MATTERS IN BRIEF

- Electronics are normally hard and that makes them difficult to integrate into wearable devices or clothing, but now new soft electronics could pave the way for a whole host of new applications

The human skin, even 3D Printed artificial skin, is amazing, but in order to accommodate our bodies every twist and turn it’s got to be able to stretch and flex. Similarly, anything that’s worn tight on the body, such as sports wear, you spandex freaks you, has also got to be able to stretch and flex. It’s just common sense. But, when you’re designing the next generation of wearables, particularly when we start talking about having to use rigid electronic components, designing something that’s both comfortable and functional suddenly becomes much harder.

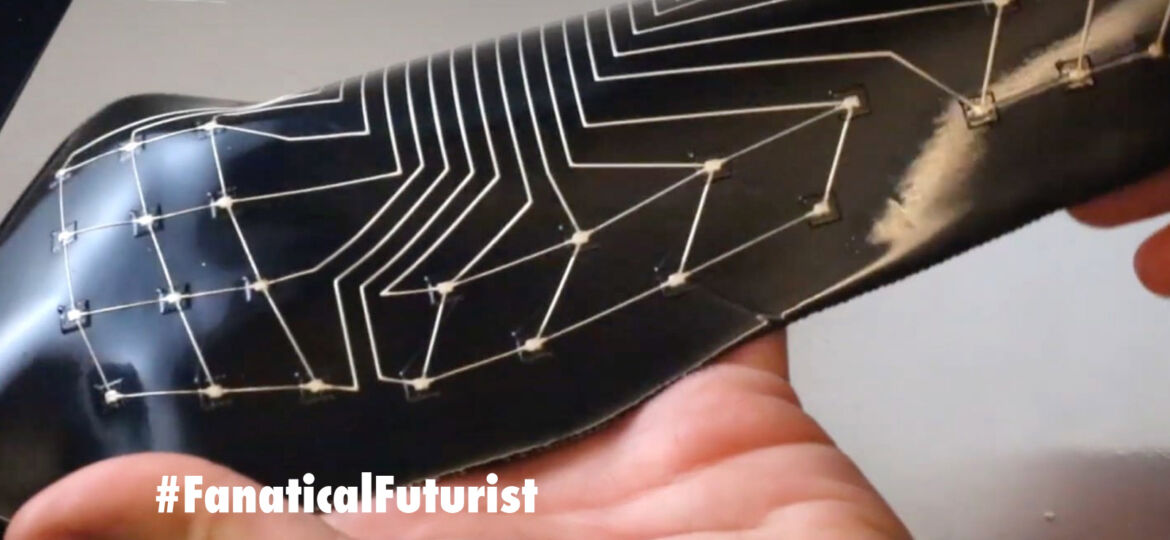

Now, a team of researchers from Harvard University and the US Air Force Research Laboratory has created a new 3D Printing technique for soft electronics that they call “Hybrid 3D Printing,” that integrates soft, electrically conductive inks and materials with rigid electronic components into a single, stretchy device.

The new device in action

“Using this technique we can 3D print the electronic sensors directly onto the material, digitally pick and place electronic components, and print the conductive interconnects that complete the electronic circuitry required to ‘read’ the sensor’s data signal in one fell swoop,” said author Alex Valentine, a Staff Engineer at Harvard University’s Wyss Institute. The research is published in Advanced Materials.

The stretchable conductive ink in question is made of Thermoplastic Polyurethane (TPU), a flexible plastic mixed with silver flakes, and the team have been able to 3D print both pure TPU and Silver-TPU inks to create their new devices underlying soft substrate and conductive electrodes.

“Because both the substrate and the electrodes contain TPU, when they are co-printed layer by layer they strongly adhere to one another prior to drying,” explained Valentine, “after the solvent evaporates, both the inks solidify, forming an integrated system that is both flexible and stretchable.”

The printing process causes the silver flakes in the conductive ink to align themselves with the printing direction so their flat, plate like sides layer on top of one another – like overlapping leaves on a forest floor, and it’s this alignment that helps improve their electrical conductivity.

“Because the ink and substrate are 3D printed we have complete control over where the conductive features are patterned, and can design circuits to create soft electronic devices of nearly every size and shape,” said Will Boley, Ph.D., a post doc researcher.

In the new wearable soft sensors that are made from conductive materials that change their electrical conductivity when stretched are coupled with a programmable microcontroller chip to process the data, and to achieve this, the researchers combined the printed soft sensors with their digital “pick-and-place process” that applied a modest vacuum through an empty printing nozzle to pick up electronic components and place them onto the substrate surface in a specific, programmable manner.

Because these surface mounted electrical components, such as LEDs, micro-chips and resistors are, by nature, hard and rigid the team took advantage of TPU’s adhesive properties by applying a dot of TPU ink beneath each component prior to attaching it to the underlying soft TPU substrate. Once dried, the TPU dots serve to anchor these rigid components and distribute stress throughout the entire matrix, allowing the fully assembled devices to be stretched up to 30 percent while still maintaining function.

For example, one of the teams wearables that was made up of 12 LEDs attached to a sheet of TPU could be repeatedly bent into a cylindrical shape without any reduction in the intensity of the LEDs’ light, and without increasing the mechanical failure of the device, then, as a simple proof of concept the team created two soft electronic devices to demonstrate its potential.

The first was a strain sensor that resulted in a wearable sleeve like device that indicated how much the wearer’s arm was bending, and the second was a pressure sensor in the shape of a person’s foot whose deformation patterns allowed them to create a visual “heat map” of what happened to the persons foot when they walked around.

While the team is still working on optimising their new technique they say it has a myriad of potential use cases, and in the future spandex might not be all you’re wearing down the gym. Think of comfortable wearable devices that can predict when you’re going to be ill, or tell your doctor how fast your new regenerative bandage is healing your skin, or, even worse, that can tell your partner you’re slacking off down the gym when you’re actually supposed to be exercising. The possibilities for health and wellness, and many things asides, like arguments, are limitless.