WHY THIS MATTERS IN BRIEF

- The colossal distances involved in getting to Mars means that shipping equipment to Mars will be an expensive herculean effort so experts want everything to be made in situ

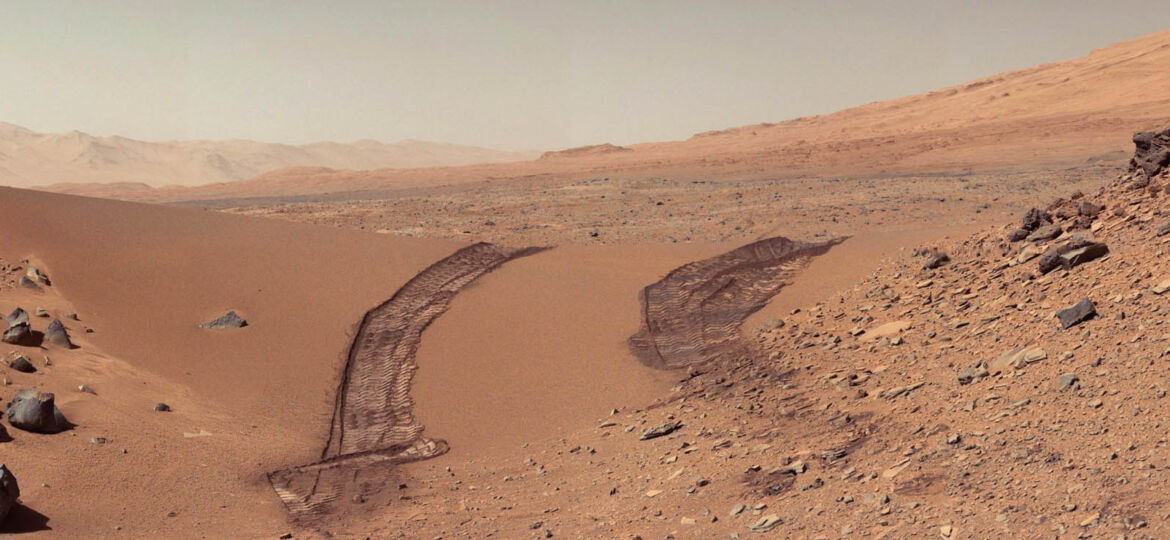

A new 3D printing technique could let the first humans on Mars print everything from tools to housing out of a tough rubber like material using nothing more than Martian dust, and there are multiple advantages. Firstly they’d be able to print everything on demand, as and when they needed it, but secondly, and equally as important it would mean that companies, like Boeing, NASA and SpaceX, who are headed to Mars in the near future, wouldn’t have to transport hundreds of tons of equipment or supplies.

“For places like other planets and moons, where resources are limited, people would need to use what’s available on the planet in order to live,” says Ramille Shah, a materials scientist at Northwestern University in Illinois, “our 3D printers open up the ability to print different functional or structural objects to make habitats beyond Earth.”

Trips to Mars will need spaceships, such as the forthcoming SpaceX Falcon Heavy, big enough to carry much more fuel and supplies than previous spacecraft, and sending care package after care package from Earth just won’t cut it. This is why so far every plan to colonise Mars, and the Moon for that matter – something that the European Space Agency (ESA) will start work on this year with their Moon Village – requires astronauts to be able to manufacture their habitats, such as the one NASA debuted recently, and other equipment, from their local environment using a combination of 3D printing and NASA mining robots like RASSOR.

One step towards achieving that goal would be to develop a “super tool” that could be used to quickly manufacture any other desired tool or object, using local resources, and to that end, Shah and her colleagues wanted to see what they could make using nothing more than the most abundant material on Mars and the Moon – dust.

In order to test their ideas the team used simulated dusts based on real lunar and Martian samples. The synthetic dust contains mixtures of aluminum oxide, silicon dioxide, iron oxide and other compounds, and they developed a process that combines simulated lunar and Martian dust with solvents and a biopolymer to create “extra-terrestrial” inks.

The inks were then 3D printed into different shapes using an extruder and in the end the objects, which it has to be said look like chocolate replicas, and which were 90 percent dust, were tough enough and flexible enough withstand the rolling, cutting and folding needed to print almost any 3D shape.

“We even 3D printed interlocking bricks, similar to Legos, that can be used as building blocks,” says Shah.

While rubbery materials could have their uses, as a next step, Shah and her colleagues are now trying to figure out a way to heat these rubbery polymers so they harden like ceramics, and if what they’ve accomplished so far is anything to go by they should be successful.

So here’s to living in a rubbery house on Mars – and as the traditional saying goes, people who live in rubber houses shouldn’t throw bricks.