WHY THIS MATTERS IN BRIEF

The benefits of manufacturing products in space are clear, but it’s still complex and expensive, this technology could help make space based manufacturing a commercial reality.

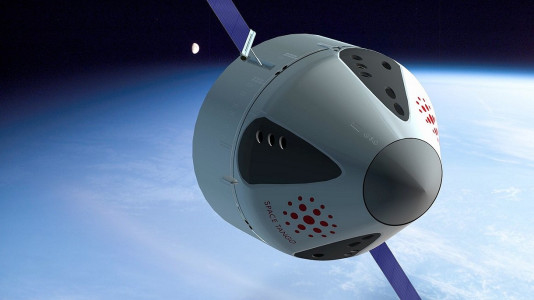

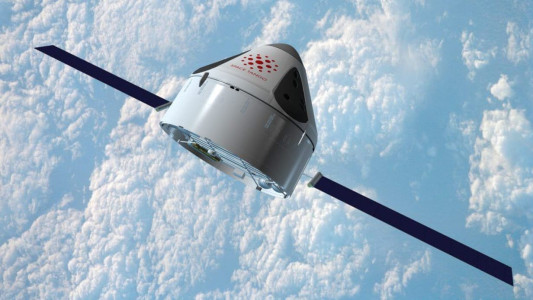

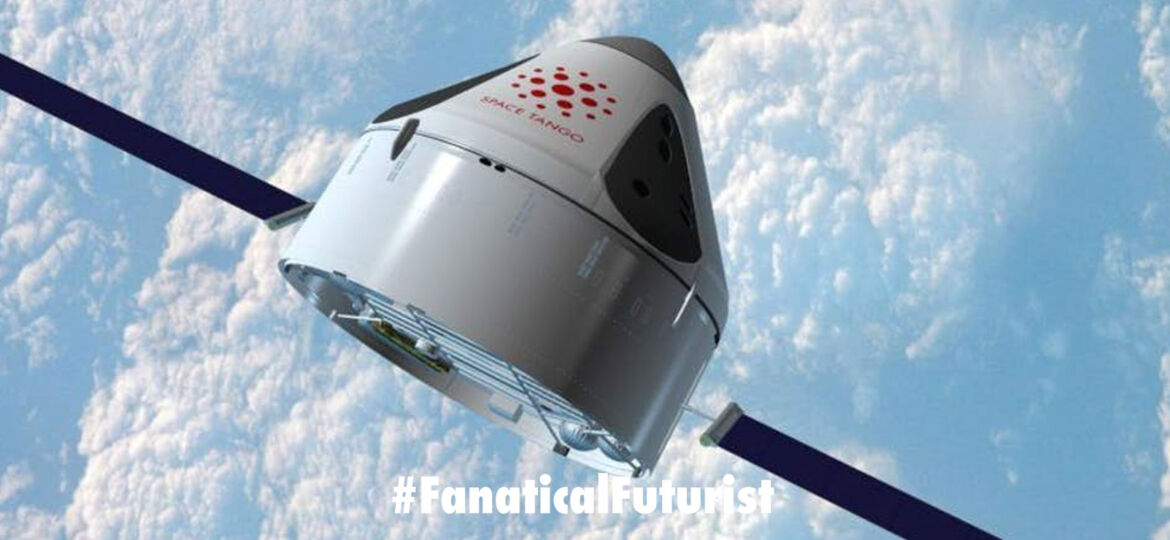

Over the past year or so I’ve been seeing more and more references made to not just space based manufacturing, but autonomous robotic space based manufacturing, with even the world’s richest Man Jeff Bezos, CEO of Amazon, announcing recently that he wants to move heavy industry off Earth with his space exploration company Blue Origin. And now, thanks to recent advances in commercial spaceflight, which means private companies can send more equipment into orbit orders of magnitude cheaper than ever before, for example, thanks to Elon Musk’s SpaceX reusable rocket technology, a company called Space Tango has announced that it’s developing its own “autonomous, robotic orbital platform that will use microgravity to produce a range of items,” from materials to medicines, for a range of industries.

Set to launch sometime in the middle of the next decade, the company’s ST-42 platform takes advantage of new orbital manufacturing techniques that were first developed and mastered on the International Space Station (ISS).

Though commercial spaceflight has been around for some time, it’s been largely confined to building spacecraft, delivering payloads to and from orbit, or gathering data, such as real time global video surveillance, and real time radio tracking, that can be sold to customers. However, weightlessness, the ability to control the environment, and the other unique properties of space hold the potential for jump starting a whole new industrial revolution – something that wasn’t lost on a team from Australia recently when they had to sky dive from a plane to test the effect of gravity on the growth of Metal Organic Framework (MOF) materials that could hold the key to producing clean energy from fossil fuels, and revolutionising healthcare…

Since its deployment the 15 partners that run the ISS have conducted hundreds of experiments aimed at progressing the development of new “orbital industries,” as they’re becoming known, and now Space Tango is looking to take the next step of creating products for the biomedical and other technology enterprises using their own small-scale autonomous orbiting factory.

According to the company, the unmanned ST-42 will be used on a series of missions to orbit and then return to Earth. Early missions will be used to study technology applications and materials production, but later biomedical missions will adhere to the US FDA Current Good Manufacturing Practice (CGMP) regulations governing items made for patient therapeutics.

Space Tango hopes that ST-42 will not only help to develop a Low Earth Orbit (LEO) industrial sector worth billions, but also help advance all space based manufacturing endeavours.

“With our TangoLab product line on the ISS, Space Tango has begun to pinpoint the applications and understand the unit economics of building high value products in microgravity for Earth,” said Twyman Clements, president and CEO of Space Tango. “This platform [ST-42] is the logical extension of this work and will create a new category of capabilities for LEO commercialisation in the space economy. Our experienced team has crafted not only a vision for the future of manufacturing in space but procedures, partnerships and tangible plans for executing ST-42.”

Source: Space Tango