WHY THIS MATTERS IN BRIEF

Our ability to assemble increasingly tiny things using increasingly tiny machinery is advancing all the time, and soon the breakthrough’s we are seeing will make even nanoscale products seem giant by comparison.

Not only is the creation of the world’s first molecular robot by a team from the University of Manchester in the UK an important development in the world nanotechnology it’s also a giant-tiny leap forwards in helping us one day realise the potential of tomorrow’s molecular assemblers, similar to the Chemputer, a chemical molecular assembler prototype shown off by BAE last year which one day they hope they’ll be able to use to grow drones in vats on demand, and in the future these little molecular robots could be used for medical purposes, for example, to create next generation nanobots, advanced manufacturing processes and even building molecular factories and assembly lines.

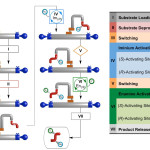

The molecular robots that the team, who were led by chemistry Professor David Leigh, cerated were used to carry out a set of molecule assembling tasks, and they even showed themselves capable of manipulating single molecular particles. The robots, which were made from of a mixture of 150 nitrogen, oxygen, carbon and hydrogen atoms, essentially worked like a molecular sized factory assembly line, performing chemical reactions under the very controlled and very specific guidance of the David and his team.

How The molecular Robots Work

The unfathomably tiny size of the robots makes it difficult for most people to comprehend the size of the small taskmasters, which even in their billions still wouldn’t be visible to the human eye, so their tiny “arms” moving about in perfect harmony is a staggering thought worthy of any sci-fi movie.

“It’s similar to the way robots are used on a car assembly line. Those robots pick up a panel and position it so that it can be riveted in the correct way to build the bodywork of a car. So, just like the robot in the factory, our molecular versions can be programmed to position and rivet components in different ways to build different products, just on a much smaller scale and at the molecular level,” said Leigh.

Replicating the work in synthetic systems is the next step for the scientists.

“It is the same sort of process scientists use to make medicines and plastics from simple chemical building blocks. Our robot is literally a molecular robot constructed of atoms just like the very simple robots you can build out of Lego bricks,” added Leigh.

There are crucial implications in medicine, materials and energy, and the developments of these tiny robots could help speed up drug discovery and even reduce the amount of material we need to make goods, along with millions of other valuable use cases.

Meanwhile, elsewhere highly regarded University of Edinburgh Chemist and Chemistry Professor Sir Fraser Stoddart summarised the effort involved in the new field.

“This doesn’t happen overnight, it takes a very long time and hundreds of very talented postdocs, and for the assembly, or handling, of fragile or sensitive materials, these robots are indispensable,” he said.

“[Curiosity about this area of research] will make the area blossom, more scientists will move into the area and it will attract more funding. You can expect the applications to appear much more rapidly now,” added American Chemical Society (ACS) President and chemistry professor Donna Nelson.