WHY THIS MATTERS IN BRIEF

- Scientists have managed to manufacture Lonsdaleite, an ultra-hard diamond found in meteorites, which could have implications for the mining and construction industries

Ever since Lonsdaleite was discovered inside fragments of the Canyon Diablo meteorite in 1967, the mysterious hexagonal diamond has divided the scientific community.

Some hypothesize that it is a separate type of diamond due to its structure while others believe that it is just a deformed version of the regular variety. Despite their differences in opinion though, scientists can agree on one thing – it’s hard – 58 percent harder than cubic diamonds, to be exact.

This makes it ideal for industrial applications but the snag is that it’s not easy to find or manufacture. In nature for instance, it is formed only during a meteorite crash. But a recent breakthrough by Australian scientists suggests it might actually be possible to create pure Lonsdaleite without the need for earth shattering impacts or four figure temperatures.

The teams new creation is part of a growing line of nanomaterials and synthetic crystals that have taken over the title of “world’s hardest material” from diamonds over the years. According to lead researcher Jodie Bradby from the Australian National University (ANU), what makes this particular diamond so special is that it is the purest Lonsdaleite ever produced and even more remarkable is its nano-crystalline form, which could make it stronger than the ones that occur naturally.

“The hexagonal structure of this diamond’s atoms makes it much harder than regular diamonds, which have a cubic structure. We’ve been able to make it at the nanoscale and this is exciting because often with these materials ‘smaller is stronger,'” says Bradby.

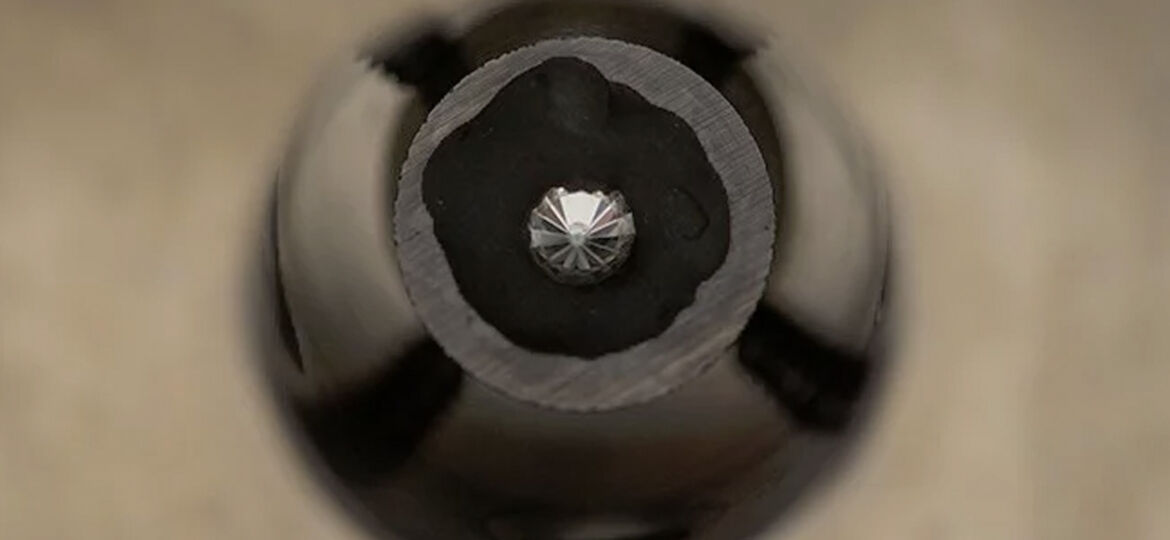

To create the Lonsdaleite, the researchers placed a piece of glassy carbon inside a diamond cell anvil, itself no stranger to creating ultra hard materials. The pressure in this chamber, which consists of two flat faced diamonds facing each other, is akin to what you’d find deep inside the Earth. Using this device, they subjected the carbon to pressures up to 112 GPa at 400 degrees Celsius – less than half of what was previously used in an unsuccessful lab experiment – for two hours.

And since the Lonsdaleite was so tiny, they almost missed seeing it. David McKenzie, a physics professor at the University of Sydney who was also part of the study, describes it like a little shoulder on the side of a peak.

“It didn’t mean all that much until we examined it later on in Melbourne and in Canberra and we realised that it was something very, very different.”

As for the applications of this crystal, Bradby says that it is unlikely to find its way onto any engagement ring.

“You’ll more likely find it on a mining site, or being used in construction in boring equipment” she says, “any time you need a super hard material to cut something, this new diamond has the potential to do it more easily and more quickly.”

[…] Source link […]