WHY THIS MATTERS IN BRIEF

3D printing is a revolutionary manufacturing technology, and it is already transforming everything from materials, food, and human organ transplants, to everyday items.

Love the Exponential Future? Join our XPotential Community, future proof yourself with courses from XPotential University, read about exponential tech and trends, connect, watch a keynote, or browse my blog.

Love the Exponential Future? Join our XPotential Community, future proof yourself with courses from XPotential University, read about exponential tech and trends, connect, watch a keynote, or browse my blog.

Hermeus, who previously worked with NASA and the US Air Force to develop the first ever hypersonic presidential jet, has announced that it’s been working with Velo3D to 3D print hypersonic jet components and wants to ramp up the technology so it can eventually use it to 3D print an entire aircraft airframe – which would be a world first. The advantage of 3D printing a hypersonic jet’s body is that the material used to print the body itself can be carefully designed and crafted to withstand temperatures that can exceed those found on the surface of the Sun.

To do so the company has obtained a bunch of Sapphire and large format Sapphire XC printers, an end-to-end metal additive manufacturing solution with which they intend to print the Mach 5 Chimera and Quarterhorse planes.

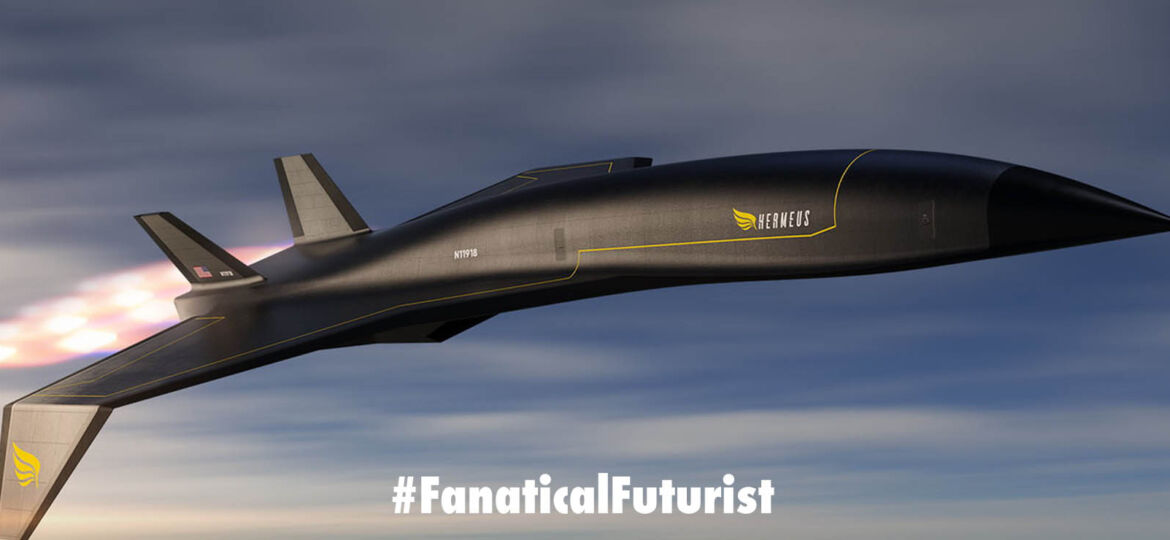

The new hypersonic jet . Courtesy: Hermeus

In time the company also wants to make its hypersonic aircraft, which travel at Mach 5 or roughly 3,800 mph, commercially available for flights and airports, so it’s handy that these 3D printers are made for high volume manufacturing.

“Metal additive manufacturing is a core component of our plan to vertically integrate production,” said Glenn Case, CTO at Hermeus. “As we explore the capabilities of Velo3D’s additive manufacturing technology, we’ll be looking for ways to increase performance, consolidate components, reduce the weight of our aircraft, and minimize external dependencies,” Case also added.

Stating that hypersonic aircraft can be quite challenging for the aviation industry, Velo3D CEO and founder Benny Buller stated that even if the speed, temperature, and vibration that Hermeus will reach are different from regular aircraft, Sapphire and Sapphire XC printers will not let Hermeus down.

“There are not many teams with the deep experience in hypersonics, aviation, and space flight that Hermeus has, and we’re truly honored to provide Sapphire printers to help them achieve their goals. I have no doubt that they will bring their vision to life and make the hypersonic commercial flight a reality.”

Velo3D is essentially a metal 3D printing technology company, and the company’s solution enables customers in space exploration, aviation, power generation, energy, and semiconductors to innovate the future in their respective industries by unlocking a wide range of “design freedom.”

The Sapphire printers use a specialized protrusion tolerant non-contact re-coater that almost completely eliminates the risk of part collisions, dramatically increasing yields, and enables a printing process that allows lower angles and overhangs down to zero degrees, thin leak tight walls, large diameter, and extremely small inner tubes, with little to no supports.

Hermeus was founded in 2018 with the ambition of dramatically accelerating air travel and have been building and testing their aircraft ever since, and when commercialised we could finally see passengers cross the Atlantic in 90 minutes – more than twice as fast as the Concorde.

Hermeus is also collaborating with government organizations to create the first line of autonomous aircraft that derisk the technology and address pressing national security issues on its way to hypersonic passenger aircraft.