WHY THIS MATTERS IN BRIEF

As the cost of launching equipment and people into space plummets the reality of colonising other planets is getting closer.

It’s one thing to send an astronaut to Mars to be an extraterrestrial tourist for a few hours. But if humanity wants to actually colonize our neighbouring planets, like Elon Musk and SpaceX are planning on doing from 2024, then we’re going to need more than rockets, we’ll need the tools to construct the buildings, and possibly tunnelling equipment to spare the colonists from the deadly radiation.

For the last five years, a lean internal team of engineers at the Kennedy Space Center has taken a different approach to solving big problems – NASA’s literal and metaphorical “moonshots.” It’s called the Swamp Works lab, and its members experiment and take risks in the hopes of accelerating research and making bigger breakthroughs. And one of the problems Swamp Works has set its sights on? How to build on other planets.

The problem sounds simple… it’s far too expensive to transport heavy, cumbersome building materials to space, and it’s not practical for humans to spend the time and energy on construction in a harsh environment. So Swamp Works’ engineers are designing robots that use local materials, regoliths, which are just basically a type of crushed rock that’s plentiful on both the Moon and Mars, to build structures that can withstand extreme environments, micrometeorites, and radiation from the Sun.

The other week Swamp Works shared details of how it’s using a combination of regolith and plastic polymer to 3D print its first large-scale construction prototype. But rather than printing a Martian structure, the group printed what’s known as a Jersey barrier, the type of barricade you probably see on the side of the highway every day. Here on Earth, these barriers need to be able to withstand the impact of a car hurtling into them which makes them the perfect test case for the atmospheric pressure that extra-terrestrial architecture will need to endure.

Jersey barriers have an internal structure that looks almost like a honeycomb, making them a challenge to print using Swamp Works’ polymer material, since horizontal shapes tend to fall apart before they can harden into place. To make it work, the lab partnered with engineers from Autodesk’s Advanced Consulting team, which helped refine the manufacturing process so that Swamp Works’ automated 3D printing robots could replicate the complicated lateral shapes found inside jersey barriers.

If you’re printing a building on another planet, you can’t afford any defects, so Autodesk designed specialized software that could correct the robot’s mistakes as it went, ensuring that the structures it builds will be completely functional and reliable. Swamp Works and NASA estimate that they might be able to put a prototype structure on either Mars or the moon in about five years, with a full scale launch in about 10 years – assuming that is they can get the funding.

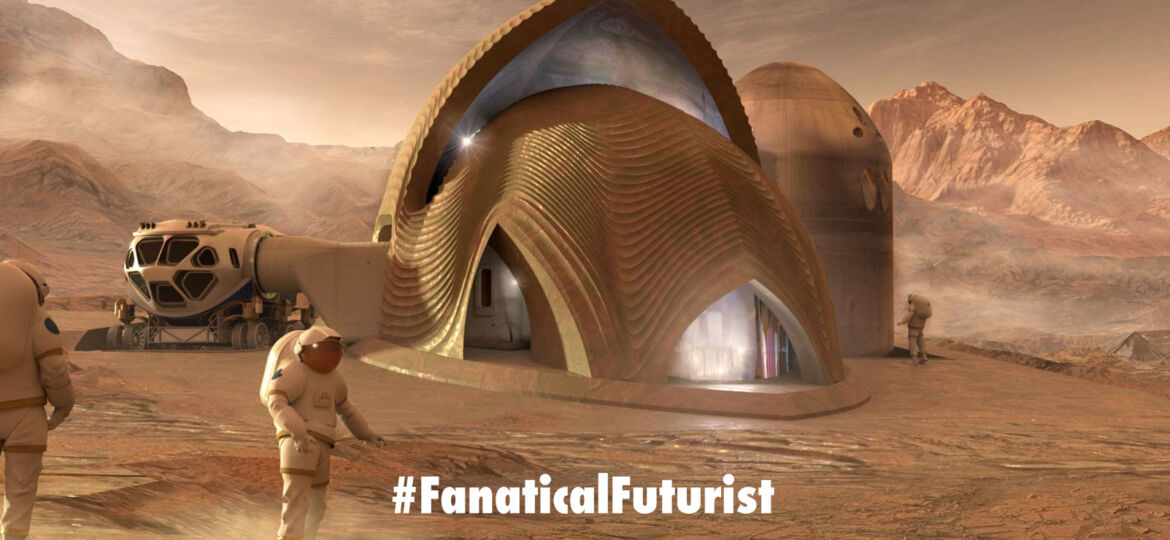

But figuring out how to construct extra-terrestrial architecture is only half the battle. As the lab works on its own prototypes, it’s also soliciting ideas through a three phase design competition. Recently the team announced the five finalists for the third stage of NASA’s 3D-Printed Habitat Challenge, through which teams of engineers proposed designs that could feasibly be 3D printed using local materials.

One concept, called Zopherus, proposes that all the 3D printing occurs inside a rocket sitting on the Martian surface. When it’s completed, the lander picks itself up and moves to another spot before beginning the process all over again. Another proposal, called Marsha, envisions the buildings as vertical cylinders since the shape can be more effectively pressurised with oxygen – plus, it provides the greatest usable floor space. While these are only concepts, all five teams will now design a custom 3D printer that can build a scale prototype of their concept by spring of 2019, and the winner will take home $2 million for their troubles.

All of this research also has implications on Earth. NASA has already partnered with the US Army to experiment with using polymers from trash combined with local rock to create building material. And for Autodesk too refining its software to suit NASA’s specifications has other benefits – the company hopes to use a material made of recycled PET bottles and regolith in industrial construction, and even to help 3D print domestic homes, like the ones other companies like Apis Cor have been busy printing over the past few years.

Here on Earth, Swamp Works is using recycled plastic in its prototypes. But on other planets, the plastic may come from other, more efficient sources like thermoplastics synthesised from carbon on Mars’s surface, or Polylactic Acid from corn grown in vertical farms on the planet. While we have too much plastic on Earth, NASA, unfortunately for them, will have to harvest their own on Mars.