WHY THIS MATTERS IN BRIEF

The way we make buildings hasn’t changed much in thousands of years, so it’s time for a faster, cheaper alternative to take center stage.

Recently a family in France were the first family to move into a 3D printed house, and the benefits of 3D printing aren’t lost on the US military who’ve already been printing everything from grenade launchers to munitions, so it’s no wonder that they’re now eying the technology to build barracks better and faster than they do today, especially as the emerging technology is relatively portable and inexpensive, and could potentially save lives if it means soldiers can build stronger, safer barracks quickly.

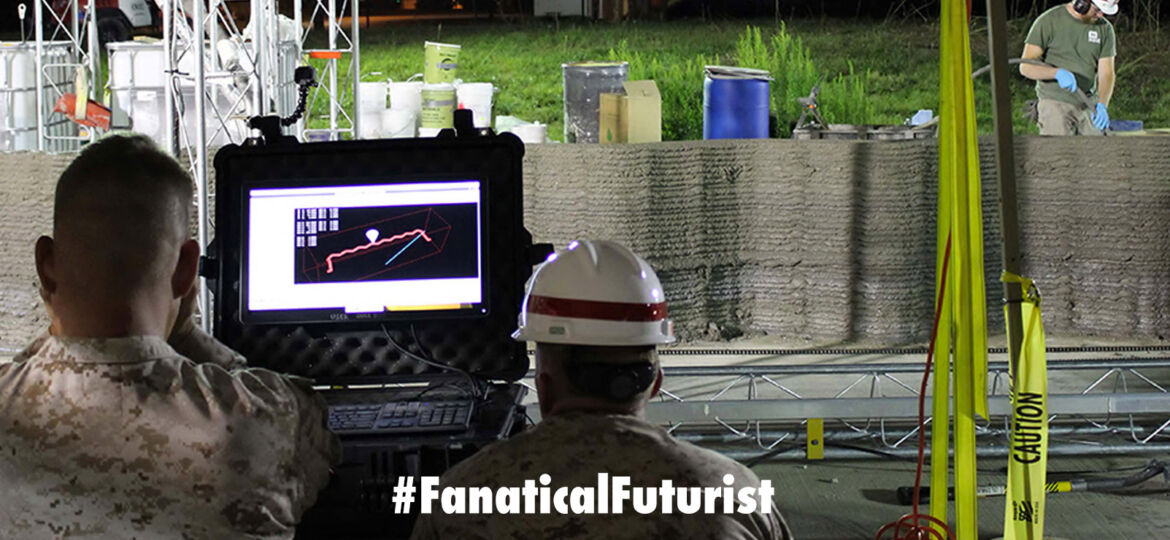

With these goals in mind the US Marine Corps Systems Command (MCSC) recently constructed a prototype concrete barracks in under 2 days with what they’re calling “the world’s largest 3D printer.” MCSC’s Additive Manufacturing Team collaborated with I Marine Expeditionary Force to build the prototype barracks at the US Army Engineer Research and Development Center in Champaign, Illinois.

The 3D printer was used to build a basic barracks hut measuring 500 sq ft (46 sq m) in just 40 hours, and according to MCSC it normally takes 10 Marines five days to construct a similar hut out of wood, so as you can see that’s a significant improvement.

The future of military barrack building?

The team started off with a computer model of the barracks they wanted to build and a 3D printer, and once they hit print the actual construction process was very similar to some of the other 3D printed concrete structures I’ve talked about in the past such as the 3D printed homes being printed in California, Dubai and the Ukraine, which could one day be built by fully autonomous construction equipment rather than people as we see today..

The printer extruded cement, which one day could be replaced by metals when the materials and the technology advances significantly enough, through a nozzle in layers to build up the undulating walls, and while we’ve no word on how the roof, windows and doors were added, like the other buildings I’ve seen built using the technology, I’d guess the Marines added them manually at the end of the build.

The Marine Corps is now carrying out more research to see how the technology can be employed in the field and if the construction process can be refined further. One suggestion they made was that automating the pumping and mixing of the cement could speed up progress to just a day.

“In active or simulated combat environments, we don’t want Marines out there swinging hammers and holding plywood up,” says MCSC Capt. Matthew Friedell, who led the project. “Having a concrete printer that can make buildings on demand is a huge advantage for Marines operating down range.”

As for what next the MCSC are now starting to actively think about deploying the technology for military operations and humanitarian aid and relief missions, and they say it could help re-house people in need more quickly than’s possible using today’s tools and techniques.

“This capability would enable a great partnership with the local community because it is low cost, easy to use, and robotics could print the buildings,” adds Friedell. “We can build better structures, houses and forward operating bases with less manpower and put fewer Marines in harm’s way.”

Source: MCSC