WHY THIS MATTERS IN BRIEF

Lower cost robots are increasingly being augmented with advanced AI and that’s accelerating the rate at which human jobs are being automated.

Robots, which might get actual rights later this year when the EU votes on the issue, have been improving a lot lately and in some cases, such flipping burgers, warehouse picking and moving pallets around a warehouse they’re already showing that they can be faster, and more accurate, than their human counterparts, and now the same artificial intelligence (AI) fuelled technologies that have spurred great advances in robotics elsewhere are coming to the slaughter house.

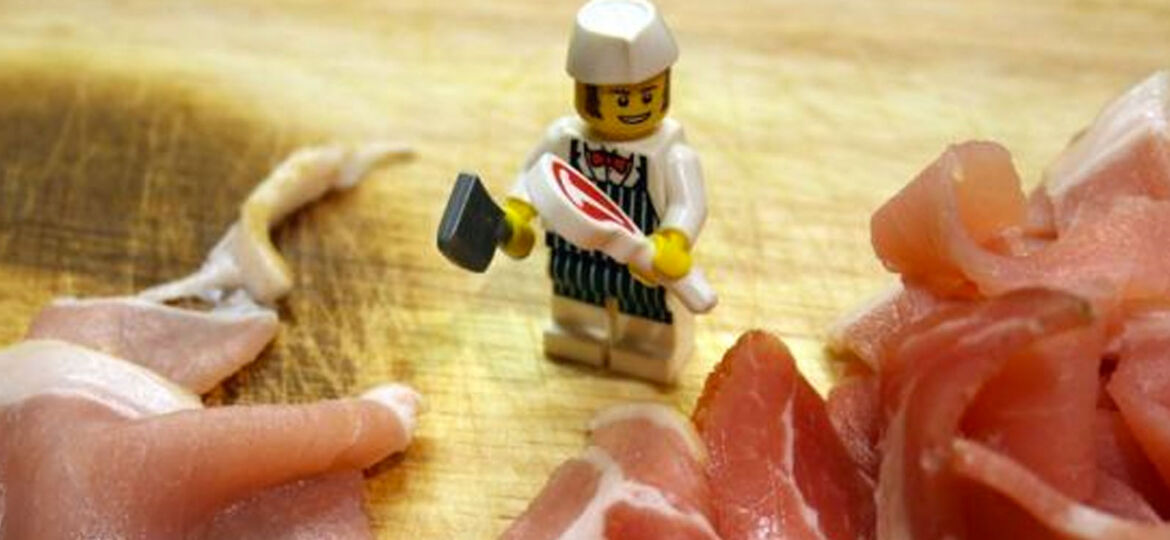

In one of Scott Technology’s “lamb boning rooms,” a production line of about a dozen robots strips meat from 600 carcasses an hour. Automated arms clamp onto pieces of raw lamb, while others wield guillotine style blades or small knives to cut through them.

It sounds like something out of a horror flick, but the point of all of this mechanisation is that you only need one human to oversee the whole process.

Scott, which is a New Zealand based robotics company has been developing fully automated meat processing robots for a couple of years now, and those robots are getting exceptionally good at extracting different cuts from lamb, pig, and beef carcasses.

As a consequence many meatpacking companies believe using this type of technology, rather than human workers, will make processing more efficient, and cheaper, in the future and they’re looking to embrace more of it, not less. And that’s bad news if you’re one of those workers.

One of the technology’s latest fans is the world’s largest meat producer, JBS, who have already invested in the technology and Scott’s now working with them to take the technology to the US market.

In Scott’s lamb boning rooms, the robots work together to form an assembly line, with each one performing one specific step of the process.

The first robot takes X-rays and a CT scan of the carcass, which generate a 3D model of its shape and size, and based on what the system sees, another robot drives rotary knives between the ribs and cuts through the hanging carcass, using the spinal chord as a reference point.

There’s also a robot that sorts the cuts and moves the carcasses to specific conveyor belts, and another that weighs them, packs them, and gets them ready for shipping. On average, the bots make the correct cuts and wrap the pieces with 90% accuracy.

Many meatpacking plants use automated machines already, but Scott’s automated systems are unique because they use AI.

Unlike most machines, which use a pre-programmed carcass outline, Scott’s robots look at the shape of each individual carcass and make specific cuts accordingly. The technology’s algorithms then leverage deep learning, which allows the robots to become smarter over time as they collect data about the carcasses they encounter.

Back in Australia and New Zealand two of the largest meat processing factories are using the technology to process over a million carcasses a year, and they’ve found that the robots also eliminate the costs of human error, so plants can wind up with less wasted meat, more accurate sorting and weighing, and fewer injuries.

While some meat processing plants outside the US have already started using robots, American plants have thus far largely held onto human workers. That’s partially because companies like Scott are just starting to develop boning technology for beef, so their systems aren’t as advanced yet as the systems for lamb. The average American consumes much more beef, about 61 pounds per year, than lamb, about one pound per year, so that’s what most US plants process.

The average New Zealander or Australian, on the other hand, consumes about 26 pounds of lamb annually, so the majority of Scott’s meat processing bots currently operate in those countries.

Cow carcasses are harder for the robots to work with because they’re larger and require more heavy duty machinery. Cows also have more muscle groups, and it can be difficult for a computer to distinguish between them, but Scott’s working on more precise robots for beef, and they debuted three types of beef processing robots in 2015, but they’re not ready for a massive international rollout yet.

Another challenge is that Scott’s machinery needs routine maintenance and repairs. The current cost for upkeep of the bots can often be more expensive than employing human workers.

“Our goal is to have them in all the plants for beef and pork worldwide,” says Michael Hopkins, Scott’s CEO, “but we’re only going to get to that point if we can continue to improve the safety and the yield – and do it with a lot less people.”