WHY THIS MATTERS IN BRIEF

Five percent the density of steel and ten times stronger, 3D graphene is the world’s strongest lightweight material.

It’s incredibly strong and has unique electrical, thermal, optical, and chemical properties, and naturally it only exists in 2D but now a team at MIT have developed a sponge like 3D version of the wonder material that has only five percent of the density of steel, but that’s ten times stronger. And the numbers, and types of applications could be ludicrous.

Graphene has long fascinated material scientists, but in its normal form it consists of 2D flat sheets that are a mere atom thick, yet can theoretically stretch indefinitely in breadth and width. In order to make graphene a practical engineering material, it needs to be coaxed into a 3D form, but so far efforts to do so have been several orders of magnitude weaker than predicted.

Hoping for better chances of success, the MIT team concentrated less on the material itself and more on its geometrical configuration. To do this, they analyzed graphene’s behavior down to the atomic level, then used the data to create a mathematical model to match the observations. From this, they were able to generate computer models that could imitate the loads in tensile and compression tests.

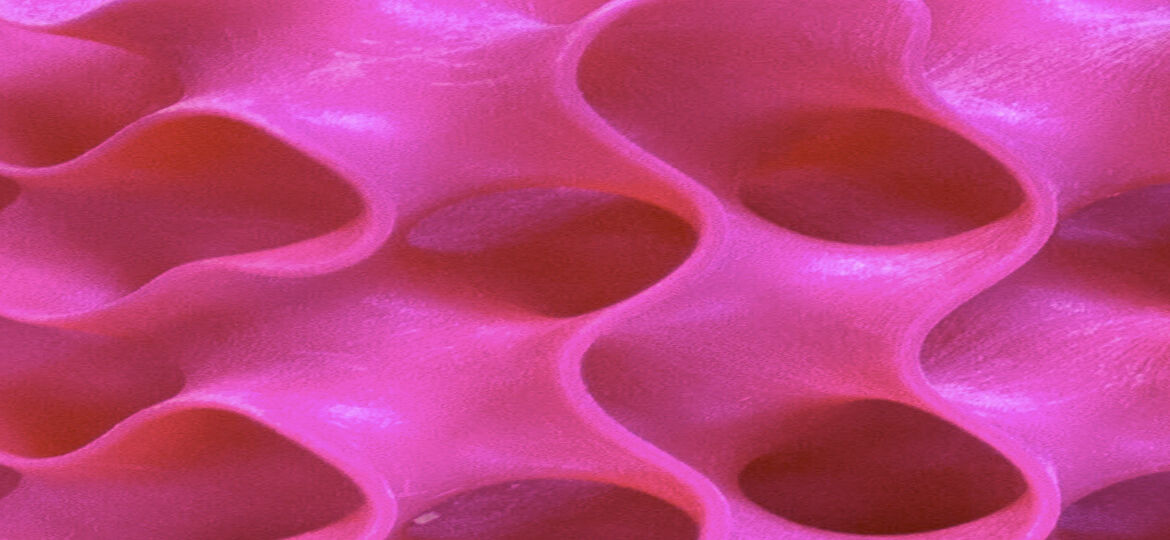

The team found that by compressing small flakes of graphene under heat and pressure, they could create strong, stable porous structures that were similar to coral and had an enormous surface area to volume ratio. According to the team, these shapes allow the 2D graphene to form strong structures in the same way that sheets of paper can be folded and rolled into much stronger forms, including cylinder and corrugations, that can hold substantial loads.

Using this as a starting point, high resolution 3D-printed models were constructed out of plastic of various configurations – similar to the “nerf-like” porous structures called gyroids that graphene form naturally, though thousands of time larger. According to MIT, these shapes are so complex that printing is the only practical way to make them. These shapes were then tested for tensile strength and compression, and compared to the computer simulations.

The tests showed that graphene in a 3D form can achieve a density of five percent of steel, but with ten times the strength. However, the researchers found that much of this had more to do with the geometrical configuration than the material. When graphene was swapped out for polymers or metals, similar gains in strength were seen.

They also discovered that some hypothetical designs didn’t work, including a 3D graphene structure that was lighter than air and could float like a helium balloon, but which the models showed would collapse under normal atmospheric pressure.

The team says that in addition to creating 3D graphene structures, the technology could be applied to other materials ranging from polymers to structural concrete and would not only produce structures that are stronger and lighter, but have better insulating properties. In addition, the porous structures could be used in filtration systems for water or chemical plants.

[…] Source link […]