WHY THIS MATTERS IN BRIEF

4D Printing could change how we construct buildings and maintain city infrastructure.

Many are only just getting their heads around the idea of 3D printing but scientists at MIT are already working on an upgrade – 4D printing. At the TED conference in Los Angeles, architect and computer scientist Skylar Tibbits showed how the process allows objects to self assemble. It could be used to install and assemble objects in hard to reach places such as underground water pipes, he suggested and it might also herald an age of self assembling robots and furniture.

TED fellow Mr Tibbits, from the MIT’s self assembly lab explained what the extra dimension involved.

“We’re proposing that the fourth dimension is time and that over time static objects will transform and adapt.” he said.

The process uses a specialised 3D printer made by Stratasys that can create multi layered materials. It combines a strand of standard plastic with a layer made from a “Smart” material that can absorb water. The water acts as an energy source for the material to expand once it is printed.

“The rigid material becomes a structure and the other layer is the force that can start bending and twisting it,” said Mr Tibbits,” essentially the printing is nothing new, it is about what happens after,” he added.

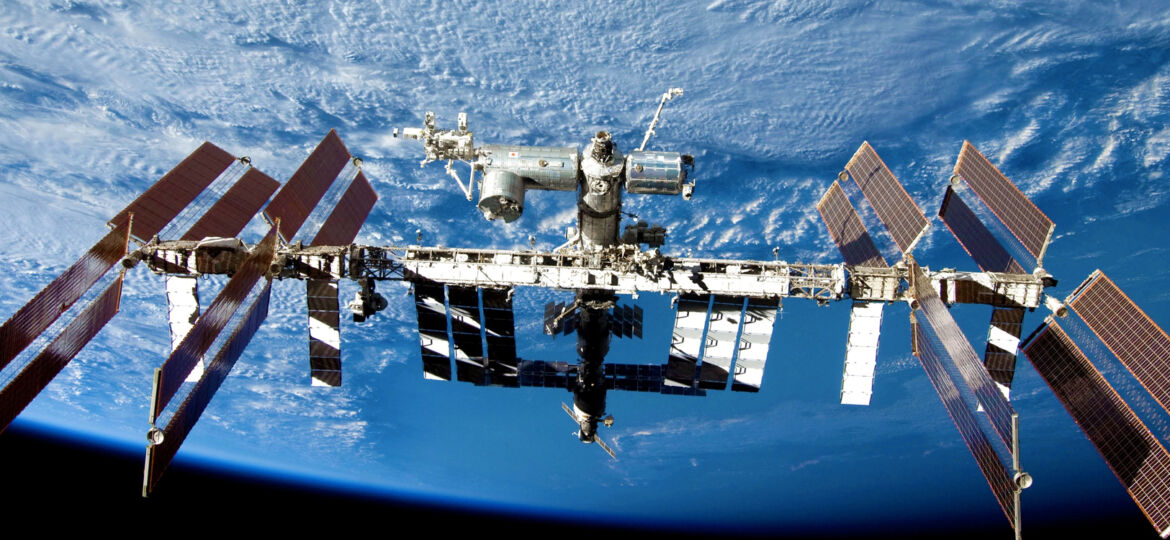

Such a process could in future be used to build furniture, bikes, cars, buildings and even space stations but for the time being he is seeking a manufacturing partner to explore the innovation.

“We are looking for applications and products that wouldn’t be possible without these materials, imagine water pipes that can expand to cope with different capacities or flows and save digging up the street.”

Engineering software developer Autodesk which collaborated on the project is looking even further into the future.

“Imagine a scenario where you go to Ikea and buy a chair, put it in your room and it self assembles,” said Carlo Olguin principal research scientist at the software firm.

The 4D printing concept draws inspiration from nature which already has the ability to self replicate.

“We already have 3D printers that can be injected with stem cells to print slices of liver,” Mr Olguin added.

“The idea behind 4D printing is to use the sheer power of biology and modify it. But it is still an elusive goal.”

The next stage for the research is to move from printing single strands to sheets and eventually whole structures and water need not be the process’s only energy source.

“We could also have heat, vibration and sound,” said Mr Tibbits.